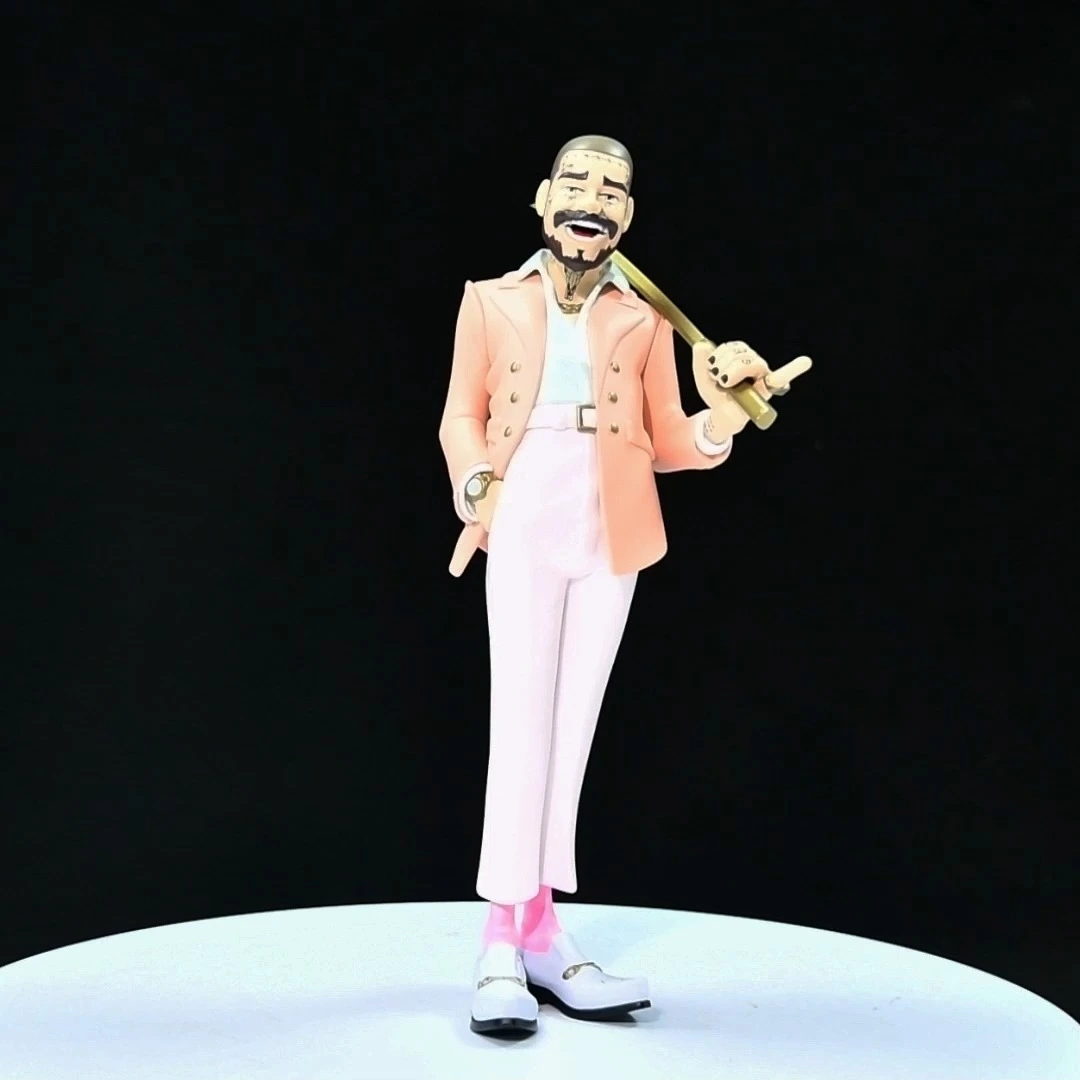

Custom Limited-edition Art Toy for Collection

Detailed Craftsmanship: Intricately designed with elaborate features and lively hues.

Customizable Options: Fully adjustable in terms of size, shade, stance, and add-ons.

Creative Freedom: Transform your ideas, characters, or brand concepts into collectible artworks.

Eco-Friendly: Manufactured using vinyl materials, ensuring safety and environmental conformity.

Size: Offered from 3 inches to 20 inches, or according to your requirements.

Packaging: Tailored packaging selections including display cartons, blister packs, or collector’s enclosures.

Design Options: Electroplated, posable, glittery, transparent, clear, glow-in-the-dark, flocked, semi-anatomical, Funko Pop-style, etc.

Production Time: Small batches completed in 10-15 days; larger orders determined by complexity.

Collector’s Items: Excellent for collectors seeking to expand their action figure collections.

Promotional Tools: Suitable for corporate mascots, giveaways, decorations, collectibles, gifts, and branding drives.

Merchandising: Developed for brands, TV programs, or movie franchises to provide unique merchandise.

Gifts: Personalized action figures make considerate presents for fans, children, or clients.

Vinyl Production Process

1. Mold making from 3D designs (aluminum/steel).

2. Mix PVC paste resin with plasticizers into a paste.

3. Inject into preheated molds, rotate to coat evenly, cure at ~200℃.

4. Demold, trim edges, and polish.

5. Apply painting, electroplating, flocking, or decals.

6. Assemble joints, accessories, and finish the product.

Rich toy solutions

Tens of thousands of toys cover the whole art styles, providing you with personalized customized solution. Multiple craft styles, give you more choices. To meet different budget ranges, create the ideal collectibles for you

Electroplating Figure

Electroplating coats plastic toy figures (like action figures, model car parts, or collectibles) with a thin, durable layer of real metal (such as chrome, gold, or nickel). An electrical current is passed through the figure, immersed in a solution containing dissolved metal ions, causing the metal to deposit evenly onto its surface. This gives the toys a shiny, metallic finish, enhances their realism, increases durability, and provides corrosion resistance.

Our team

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries, and offer continuous support even after a purchase is completed.

Vinyl Toy Production Process

The production of art toys is a very complicated process, and it also involves a variety of processes. The production of vinyl parts is a very important process in the production of art toys. The following video will show you how the vinyl parts of art toys are produced.