Wood Carving Craftsmanship

Let's briefly explore production of woooden figurines

3.cutting and Processing

Post the art toy design blueprint, cutting and processing commence. The chosen wood undergoes sawing and edging to smoothen its surface, eliminate rough edges, and refine corners. Subsequently, the wood is carved, sculpted, and perforated as per the design requirements, utilizing various woodworking tools, cutting machinery, and power tools.

4.Sanding and Polishin

The created wooden figurines may have rough sections necessitating sanding and polishing. Different grades of sandpaper and polishing machines are employed to repeatedly sand and polish the wooden figurines until achieving a smooth, even surface without rough edges or indentations.

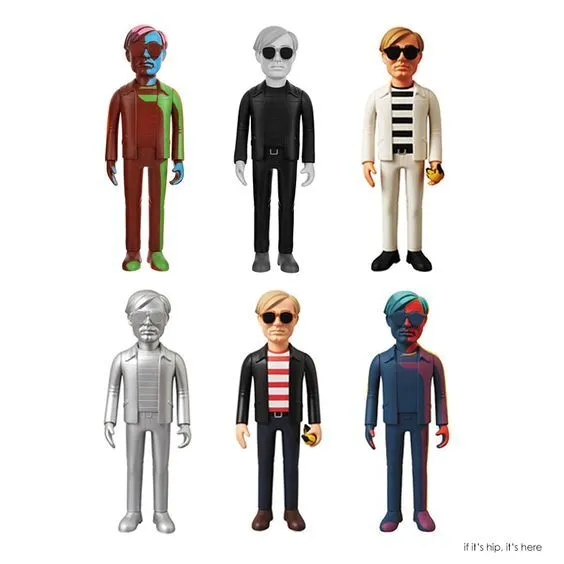

5.Painting and Coloring

To protect the wooden action figures and enhance their appearance, appropriate colors and designs are applied to their surfaces using various pigments, paints, and varnishes. While painting, eco-friendly paints containing harmless components are used, ensuring the product's eco-friendliness.

6.Assembly and Packaging

Following the completion of all processes, assembly and packaging take place. The processed toy parts are assembled per design specifications using glue, wooden nails, and screws. Finally, packaging using materials like colored boxes, paper boxes, or nylon bags is done, ensuring intactness and using eco-friendly materials for product quality and ecological sustainability.

Crafting wooden figurines requires precision, dedication to quality, and adherence to eco-friendly practices throughout the production process.